Product Consultation

Your email address will not be published. Required fields are marked *

Does nylon multifilament yarn have good tensile properties for use in high-intensity environments?

Mar 25,2025

Does nylon multifilament yarn adopt environmentally friendly technology to reduce the impact on the environment?

Mar 18,2025

Will the performance of nylon elastic yarn deteriorate during long-term use?

Mar 11,20251. Excellent elastic recovery ability

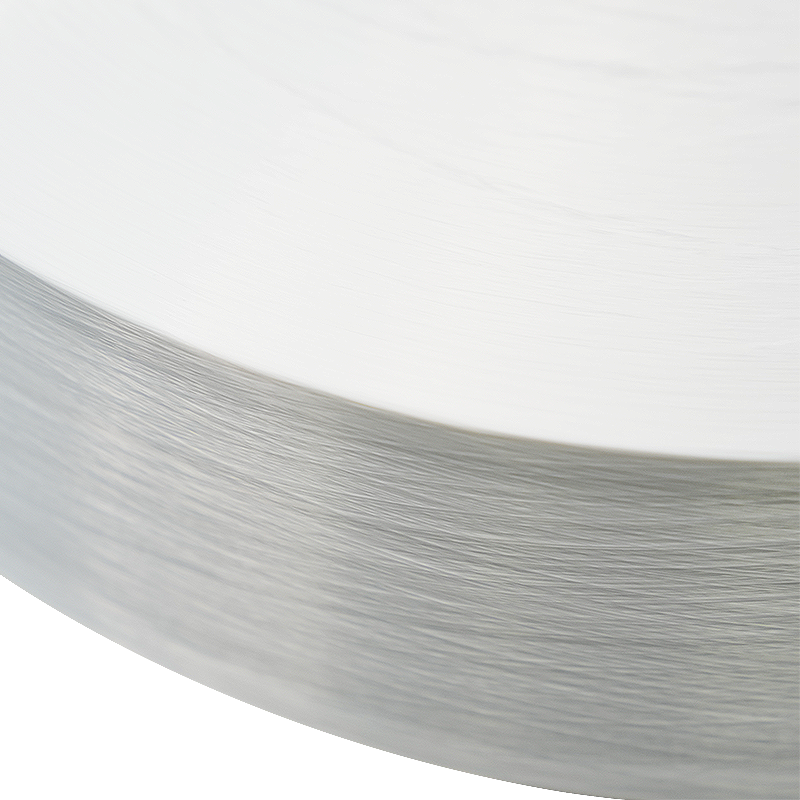

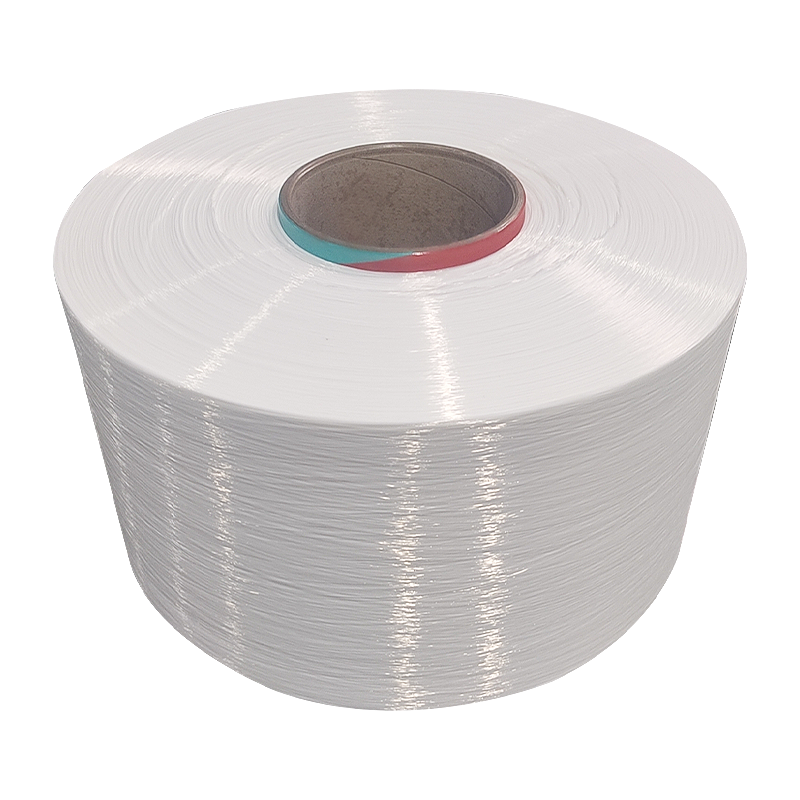

The core advantage of Elastic High Performance Polyamide Multifilament is its good elastic recovery ability. After being stretched or compressed by external force, this material can quickly return to its original shape with almost no permanent deformation. This feature allows it to perform well in application scenarios that require high elastic response, such as sports equipment, medical devices, and elastic fabrics.

2. High strength and durability

In addition to elasticity, the material also has extremely high strength and durability. Polyamide itself is a material with good mechanical properties, and the multi-filament structure further enhances its overall strength. This enables Elastic High Performance Polyamide Multifilament to withstand high-intensity stretching and wear, and maintain stable performance in harsh working environments. It is widely used in industrial fields that require high durability, such as automotive manufacturing, aerospace, and construction engineering.

3. Excellent wear resistance and chemical corrosion resistance

Wear resistance and chemical corrosion resistance are also significant features of Elastic High Performance Polyamide Multifilament. Under the test of friction and chemical corrosion, the material can maintain its surface finish and structural integrity and is not easily damaged or deteriorated. This feature allows it to perform well in situations where it needs to be exposed to harsh environments for a long time, such as chemical equipment, marine engineering and outdoor equipment.

4. Good processing performance and designability

Elastic High Performance Polyamide Multifilament also has good processing performance and designability. It can be shaped and cut by various processing methods to meet the needs of different application scenarios. The material can also be used in combination with other materials to form a composite material with multiple functions. This flexibility and designability make Elastic High Performance Polyamide Multifilament have great potential in product development and innovation.

What is the weaving process used in Woven Antiviral Yarn?

2024-07-26

How is Biodegradable Yarn degradable

2024-08-08Your email address will not be published. Required fields are marked *

Fully stretched polyester blended yarn is made of a blend of polyester and nylon. Polyester itself has good wear resistance. After full stretch processing, the strength and softness of the yarn increa...

See Details

High shrinkage blended polyester yarn has a high shrinkage rate and is suitable for textile manufacturing that requires shrinkage treatment, such as making pleated fabrics or textile shaping. Because ...

See Details

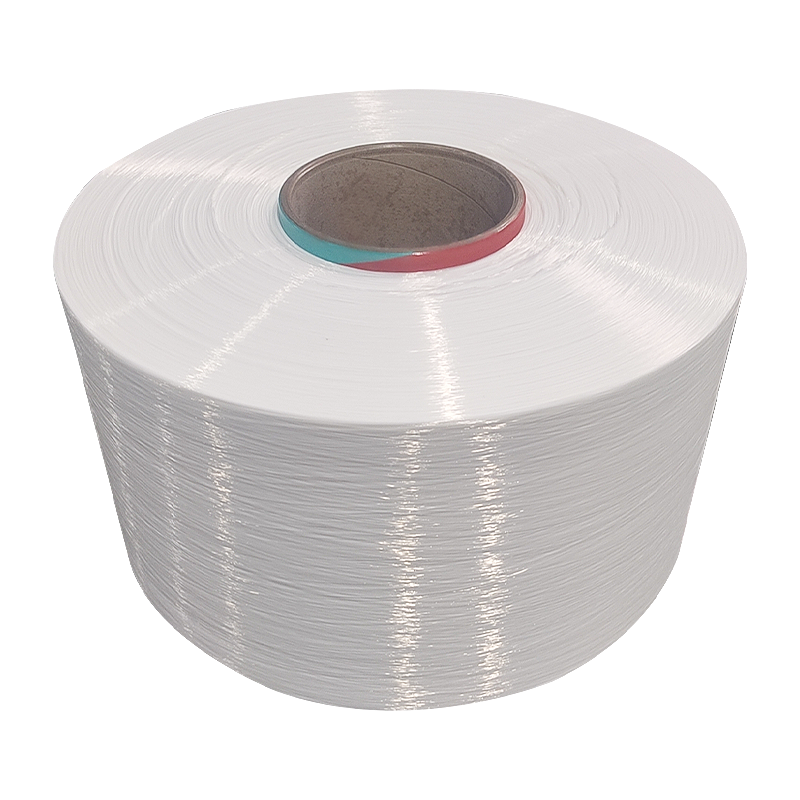

Stretch durable FDY yarn has good elasticity and can return to its original shape after being stressed, giving the textile a comfortable wearing feel and good ductility. It can fit the contours of the...

See Details

Composite fiber yarn for textile use consists of 48 monofilaments. Relatively thin and composed of multiple filaments, it adds softness and texture to the fabric. This product is suitable for the manu...

See Details

Biodegradable nylon yarn biodegrades faster in the environment than traditional synthetic fibers, helping to reduce negative environmental impacts. It also has the properties of nylon fiber, such as h...

See Details

Nylon is a synthetic fiber with good strength and wear resistance, so 40D biodegradable yarn inherits the properties of nylon fiber. It has tensile strength, abrasion resistance and corrosion resistan...

See Details

Antiviral nylon Monofilament Yarn can inhibit the survival of viruses on the surface of the yarn, which can effectively reduce the risk of virus transmission and improve user safety. The yarn has a mo...

See Details

60D woven Antiviral Yarn is thin overall and suitable for making light and soft textiles. Nylon fiber has a soft feel and good breathability. This yarn is usually used to weave fabrics and can be made...

See Details

Graphene yarns can be produced by a variety of methods, including chemical vapor deposition (CVD) and wet spinning. In CVD, graphene is grown directly on a substrate, which is then removed to obtain g...

See Details

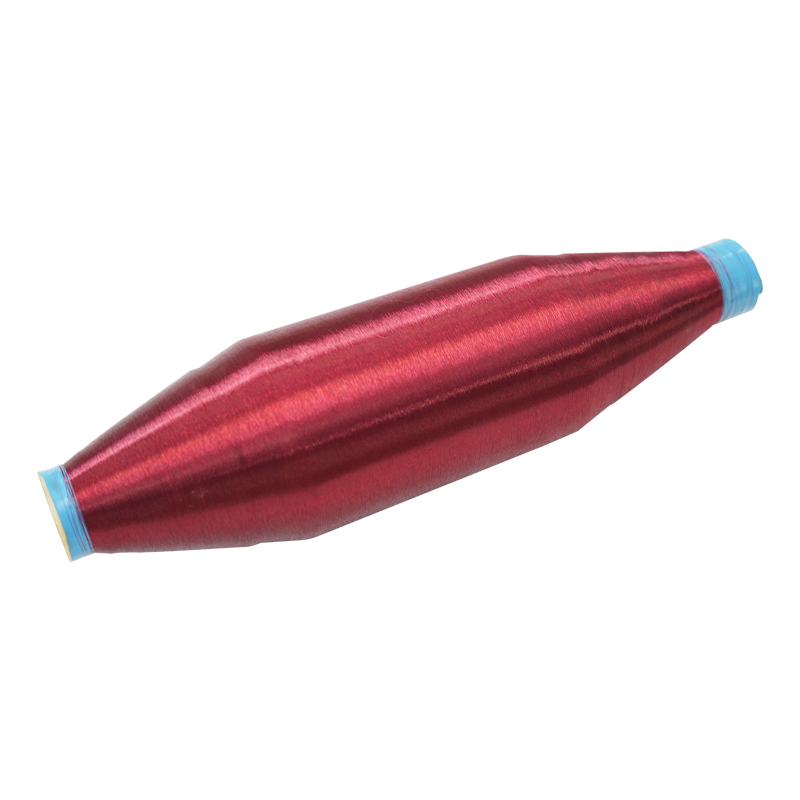

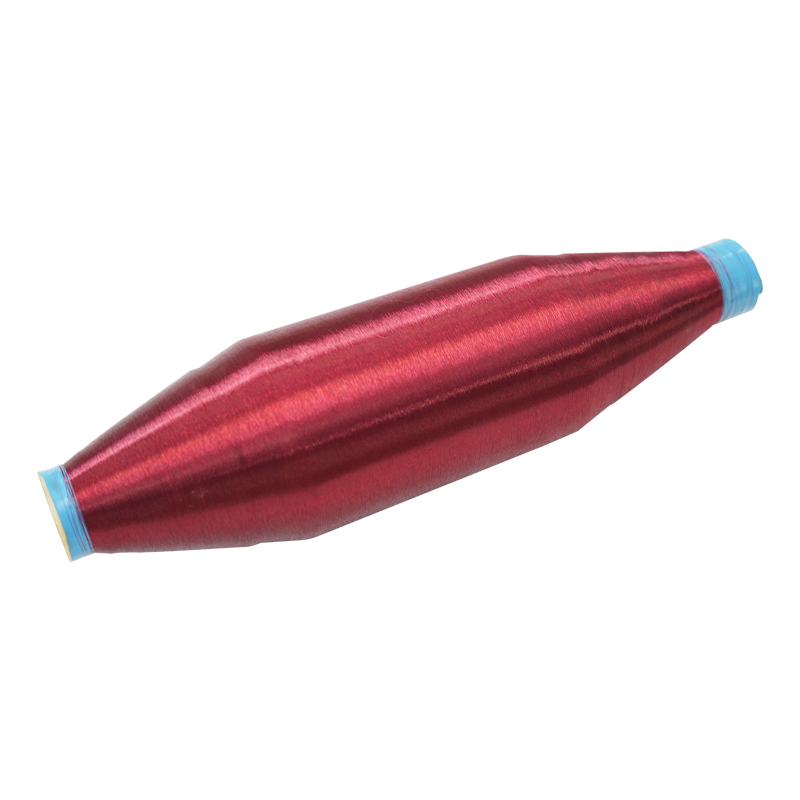

Colored Nylon Mother Yarn can be processed through spinning, drawing, dyeing and other processes to meet the needs of different textiles. It has good processing adaptability and can be made into vario...

See Details

The diameter of Durable woven nylon mother yarn is 240D, the fiber thickness is medium, and it is suitable for the manufacture of a variety of textiles. This product has good tensile strength and will...

See Details

Nylon stretch sportswear yarn is a yarn used to make sportswear and other clothing that require high breathability. Nylon fiber has good breathability, which helps to wick away perspiration and keep t...

See Details

Fully stretched polyester blended yarn is made of a blend of polyester and nylon. Polyester itself has good wear resistance. After full stretch processing, the strength and softness of the yarn increa...

See Details

High shrinkage blended polyester yarn has a high shrinkage rate and is suitable for textile manufacturing that requires shrinkage treatment, such as making pleated fabrics or textile shaping. Because ...

See Details

Stretch durable FDY yarn has good elasticity and can return to its original shape after being stressed, giving the textile a comfortable wearing feel and good ductility. It can fit the contours of the...

See Details

Composite fiber yarn for textile use consists of 48 monofilaments. Relatively thin and composed of multiple filaments, it adds softness and texture to the fabric. This product is suitable for the manu...

See Details

Biodegradable nylon yarn biodegrades faster in the environment than traditional synthetic fibers, helping to reduce negative environmental impacts. It also has the properties of nylon fiber, such as h...

See Details

Nylon is a synthetic fiber with good strength and wear resistance, so 40D biodegradable yarn inherits the properties of nylon fiber. It has tensile strength, abrasion resistance and corrosion resistan...

See Details

Antiviral nylon Monofilament Yarn can inhibit the survival of viruses on the surface of the yarn, which can effectively reduce the risk of virus transmission and improve user safety. The yarn has a mo...

See Details

60D woven Antiviral Yarn is thin overall and suitable for making light and soft textiles. Nylon fiber has a soft feel and good breathability. This yarn is usually used to weave fabrics and can be made...

See Details

Graphene yarns can be produced by a variety of methods, including chemical vapor deposition (CVD) and wet spinning. In CVD, graphene is grown directly on a substrate, which is then removed to obtain g...

See Details

Colored Nylon Mother Yarn can be processed through spinning, drawing, dyeing and other processes to meet the needs of different textiles. It has good processing adaptability and can be made into vario...

See Details

The diameter of Durable woven nylon mother yarn is 240D, the fiber thickness is medium, and it is suitable for the manufacture of a variety of textiles. This product has good tensile strength and will...

See Details

Nylon stretch sportswear yarn is a yarn used to make sportswear and other clothing that require high breathability. Nylon fiber has good breathability, which helps to wick away perspiration and keep t...

See Details

Fully stretched polyester blended yarn is made of a blend of polyester and nylon. Polyester itself has good wear resistance. After full stretch processing, the strength and softness of the yarn increa...

See Details

High shrinkage blended polyester yarn has a high shrinkage rate and is suitable for textile manufacturing that requires shrinkage treatment, such as making pleated fabrics or textile shaping. Because ...

See Details

Stretch durable FDY yarn has good elasticity and can return to its original shape after being stressed, giving the textile a comfortable wearing feel and good ductility. It can fit the contours of the...

See Details

Composite fiber yarn for textile use consists of 48 monofilaments. Relatively thin and composed of multiple filaments, it adds softness and texture to the fabric. This product is suitable for the manu...

See DetailsAddress: Duntou industrial park, haian county, nantong city,jiangsu province ,China.

TEL: +86 15850491859

E-mail: sales-betty@hsnylon.com

If You Are Interested In Our Products, Please Consult Us